ABOUT US

Alphacast is founded in 1989 to engage in the manufacturing of 1) Sheet Metal Fabricating and 2) Investment Casting. Most of its manufactured goods are exported either directly or indirectly worldwide.

As a Board of Investment promoted company, Alphacast enjoys the privilege to import duty free materials into Thailand. This allows us to source globally materials and components at best bargains, an advantage that keeps our products competitive in the ever so competitive global marketplace.

Alphacast benefits greatly from its multinational human resources. Skillful, experienced and dedicated managers and engineers to support our customers. With this group of able people, we have been able to continuously grow and excel in offering high quality products and services to our customers.

We endeavour to satisfy all customers’ needs and provide the best value. Ultimately our goal is to be a truthful and trustworthy supplier of “Total Solutions”.

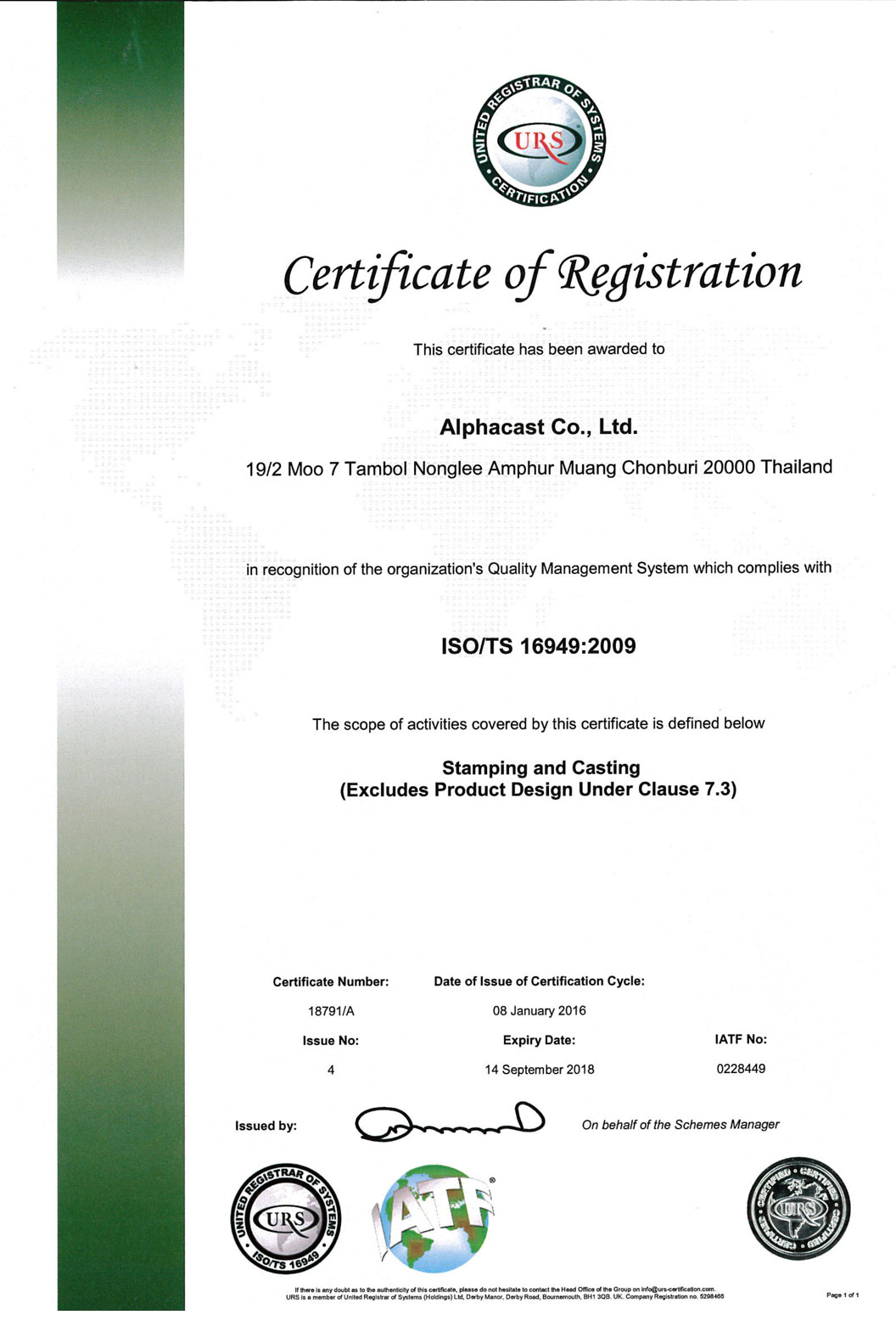

The company has obtained the following certificates :

- ISO 9001 - ISO 14001 - ISO/TS 16949

Where applicable, we are in compliance with the RoHS rules.